Air Conditioned IT Rack Cabinets Compatible with Extinguishing Apparatuses

You may submit your request for proposal here.

BKT Elektronik company produced a series of industrial rack cabinets according to IP54 air-tightness standard. The cabinets were designed in a response to market’s demand for creating cabinets compatible with 19-inch devices and suitable for the environments requiring extra safety measures. The cabinets are fitted with ventilators and their structure enables the application of the AGC Extinguishing Apparatus for fire suppressing.Submit your Inquiry

The cabinets are adjusted to be:

- fitted with the AGC Master and AGC Slave Extinguishing Apparatus-based extinguishing system

- fitted with the ventilator attached on the side of the cabinet

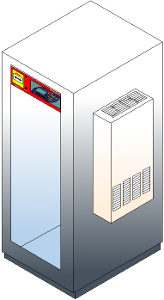

Fig. 1. Air conditioned industrial IT rack cabinet IP54 with an installed ventilator.

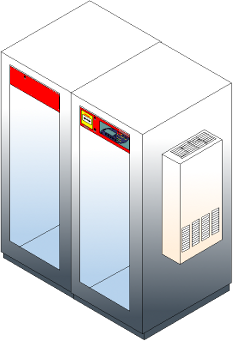

Fig. 2. Air conditioned industrial IT rack cabinets IP54 joined sideways with assembled AGC Master and AGC Slave Extinguishing Apparatuses

The solutions are dedicated to:

- server rooms where the application of the large-scale fire suppressing system embracing the entire surface of the room is impossible; server rack cabinets – constructed pursuant to an increased air-tightness standard (IP55) – fitted with an attached ventilator providing optimal cooling of the devices inside the cabinet and with AGC Master Extinguishing Apparatus (in the set of cabinets joined sideways AGC Slave Extinguishing Apparatus is also used) is the simplest, the cheapest and the most effective solution for securing the electronics against fire and poor environmental conditions.

- manufacturing spaces, store houses (increased humidity, dust etc.); the construction of the cabinet provides the maximal security level for contained devices against conditions inside i.e. a production hall. The applied solutions enable easy configuration of devices inside the cabinet. Additionally, the application of AGC Master Extinguishing Apparatus (in the set of cabinets joined sideways AGC Slave Extinguishing Apparatus is also used) secures the cabinets against the fire.

Dimensions of the produced cabinets:

- width 600 to 1000 mm

- depth 600 to 1000 mm

- height 1200 to 2200 mm according to the client’s needs

- frame bearer of the industrial IT rack cabinet is based on a certified aluminum section with an extended flange which improves the air-tightness of the casings.

Aluminum sections of the frame are connected to each other with assembly blocks which enables:

- changing of the casing’s size depending on the size of the applied equipment,

- replacement of specific parts of the cabinet (e.g. in the case of vandalism),

- increasing of the maximal load of the cabinet – up to 800 kg of impact and vibrations resistance according to IEC 61969-3 standard and shock resistance according to IEC 61969 standard,

- enormous decrease of the casing’s weigh

Structural elements of the cabinet

The standard version of the cabinet is fitted with two pairs of sections inserted in a way to enable an unrestrained positioning and configuration of space inside the casing. It also possible to provide casing for the cabinet loaded up to 1000kg. Additional feature of the cabinet is the possibility to insert backer plates of various size in the rear space.

The cabinet may be attached a steel, air-tight or glassed front and rear doors. The doors can be easily fixed on the right and left side of the cabinet. Also, their opening angle is max. 120°

Cabling System in the Cabinet

The cables are inserted to the cabinet through cable holes on the roof and floor or upper and lower part of the rear covering. Cable holes (in standard version secured by an air-tight cable glade) can be fitted with brush cable glades, foam sealed pass-through cable glades, varied in diameter standard PG outlet cable glades or the sealing of other producers can be used.

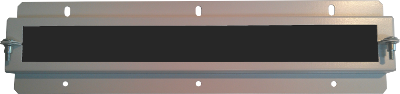

Fig. 3. Industrial IT rack cabinet IP54 – the fitting of cables

AGC Master and AGC Slave Extinguishing Apparatuses Designed for Industrial Rack Cabinets

Extinguishing Apparatus specification

Fig. 4. AGC Master Extinguishing Apparatus – front and bottom view

Air Conditioners used in Industrial Rack Cabinets

EGO is an innovative series of air conditioners which applies modern technologies and a distinguished design compatible with TEXA Rack Cabinets.

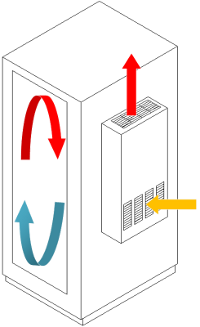

Fig. 5. Air circulation inside ventilated cabinet

Distinctive features:

- Air conditioners’ (EGO series) cooling power ranges from 820 W to 14800 W

- Air conditioner (EGO series) is installed on the side walls of the cooled cabinets

- In standard issue every type of air conditioner is fitted with an advanced electronic thermostat regulating additionally operation modes and alarms,

- Air conditioned cabinets are air-tight. The separation of the inside of the cabinet from the outside world creates a dust-free environment for the devices placed in the cabinet,

- Air conditioners are operational in harsh environment – huge amounts of dust in the air, high air humidity and oil mist in the air,

- Air conditioners are fitted with exchangeable air filters,

- Display unit in every model,

- Simple power supply system – outside socket and plug,

- Simple maintenance,

- Simple installation

Data on rack cabinets presented due to the courtesy of BKT Elektronik company.